Quicker. Stronger. Better-Built Steel

T-Hangars.

Quicken Steel designs and manufactures T-Hangars for private aircraft owners, flight schools, and regional airports across the U.S. Each structure is American-made and engineered for strength, speed, and scalability—from light single-engine aircraft to small business jets.

Our T-Hangars deliver modular efficiency, long-term durability, and architectural flexibility that meet the demands of both private and municipal aviation facilities.

Engineered for Every Class of Aircraft

Each Quicken hangar is engineered for performance, safety, and flexibility — providing scalable bay sizes up to 70 feet clear span and 20 feet clear height to accommodate a wide range of aircraft and door configurations. Our building systems combine modern steel engineering with efficient construction methods to deliver faster installation, lower maintenance, and maximum usable space.

Custom Aircraft Hangars Built Around Your Needs

From single-aircraft T-hangars to multi-bay box hangars and custom rigid-frame facilities, Quicken Hangars offers a full range of aircraft storage and maintenance building options. Every model is designed with pilots, owners, and developers in mind — whether for private use, flight schools, or FBO applications.

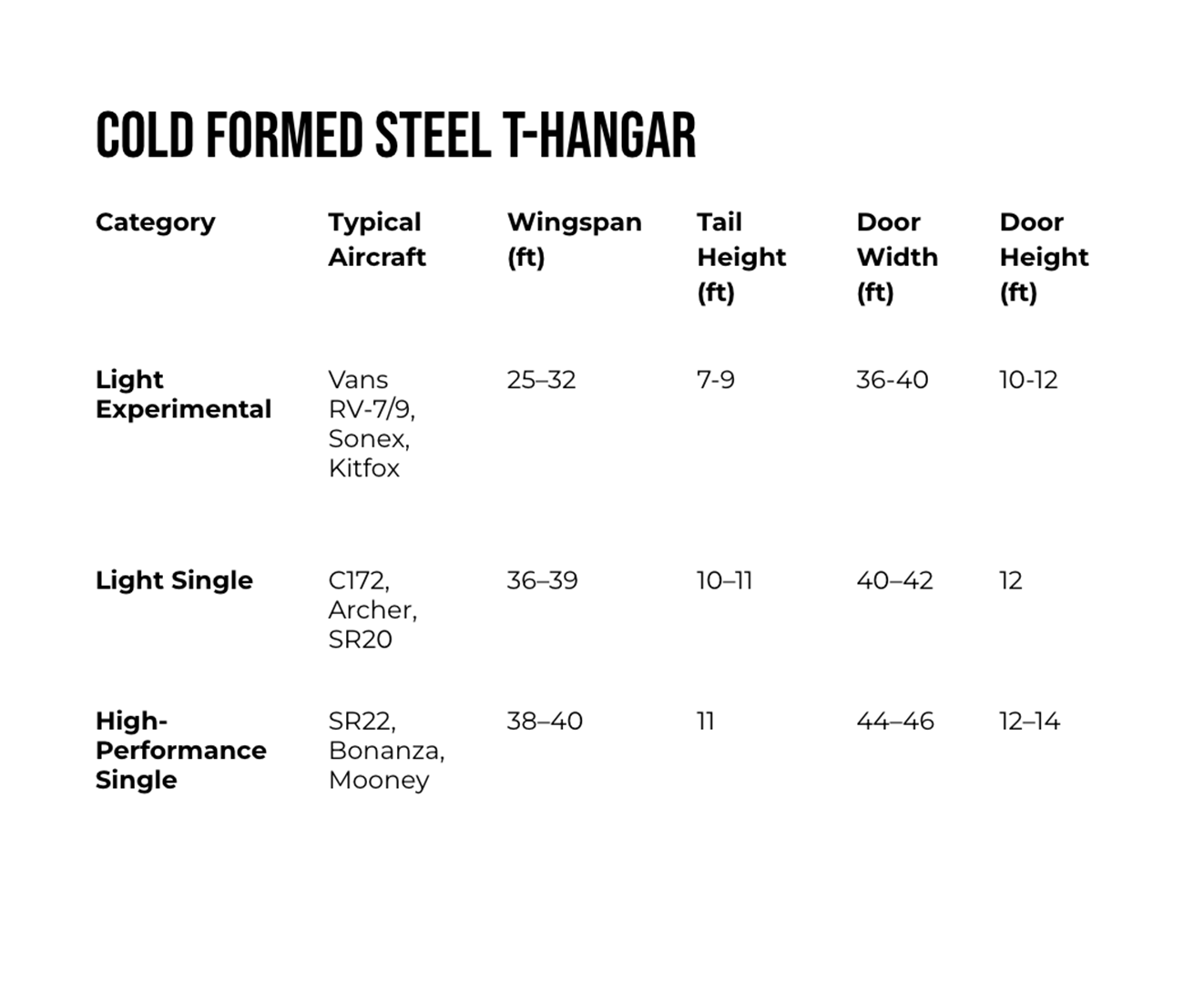

Cold-Formed Steel T-Hangars

Our cold-formed steel T-hangars are ideal for light aircraft and experimental planes, including models such as the Vans RV-7/9, Cessna 150/172, and Cirrus SR20/SR22. These hangars provide efficient individual bays with optimized door clearances and integrated drainage and insulation options. Cold-formed construction ensures long-term corrosion resistance and cost-effective assembly — perfect for airparks, flight clubs, or private pilots looking for dependable protection.

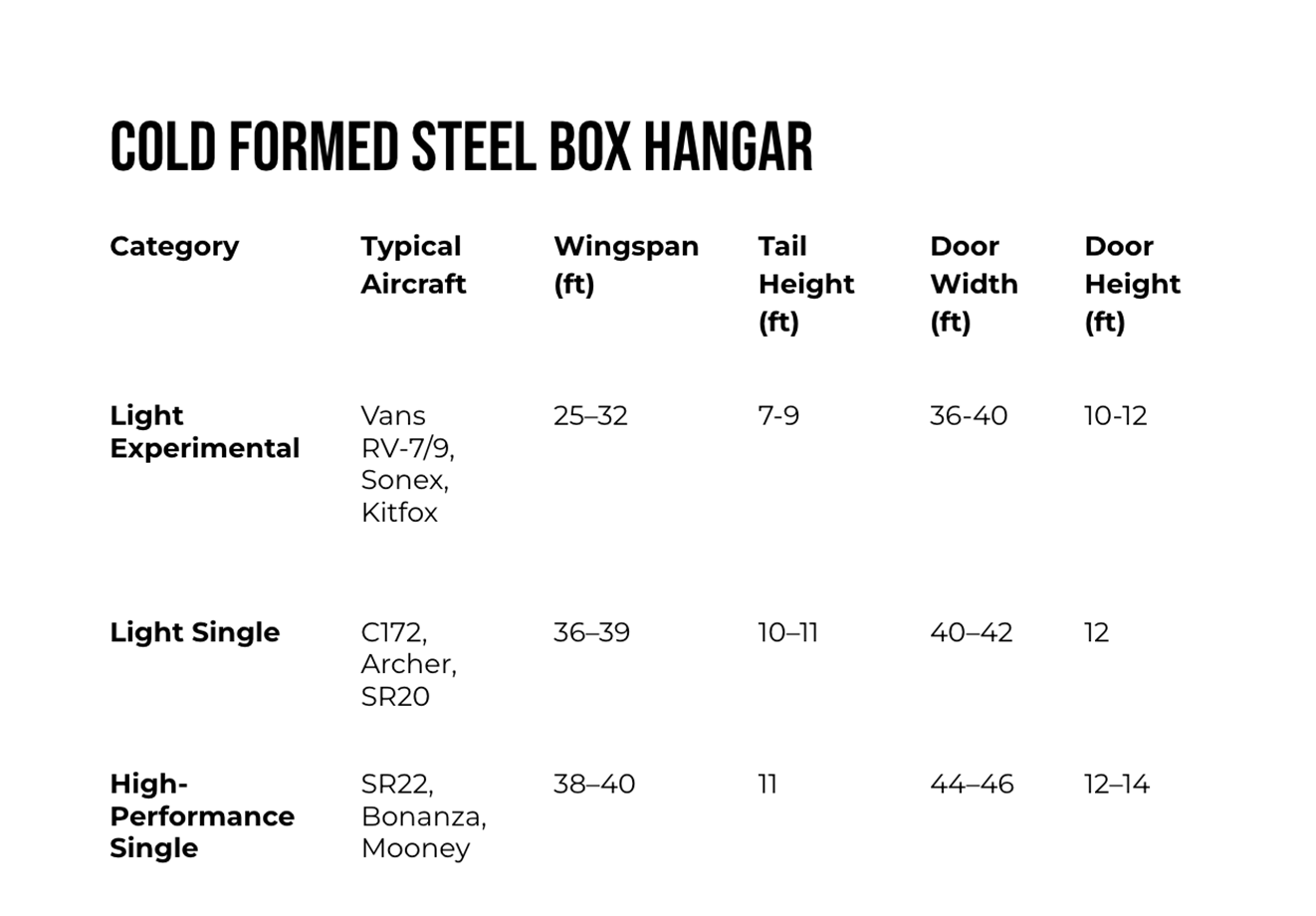

Cold-Formed Steel Box Hangars

Box hangars offer greater flexibility for larger single-engine or twin-piston aircraft, such as the Beechcraft Baron, Piper Seneca, or Cessna 414. Quicken’s cold-formed steel box hangars feature modular design, open floor plans, and easy customization for maintenance equipment, office space, or storage. These hangars combine durability and affordability, making them a smart solution for small-scale operations, charter services, or municipal airports.

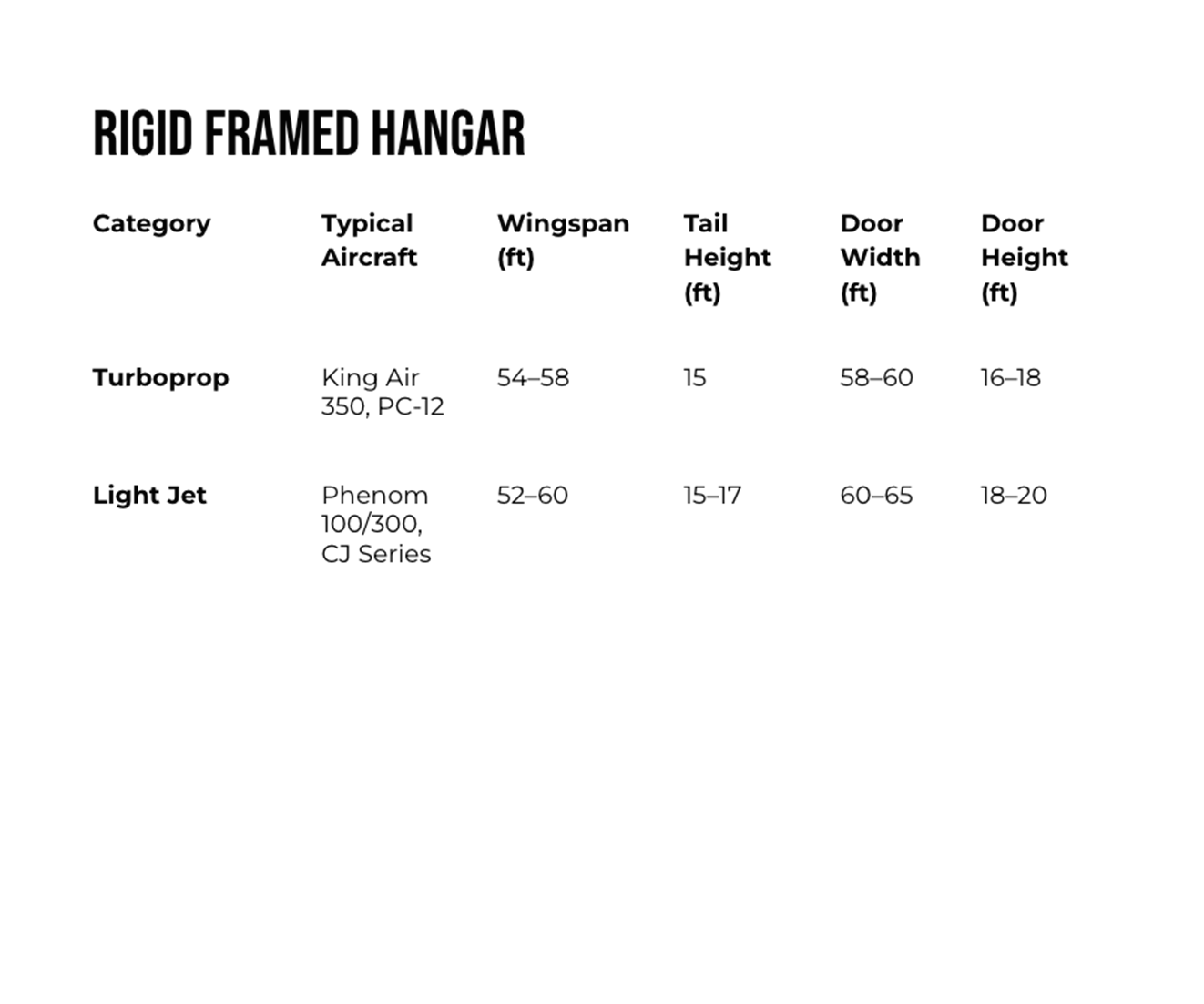

Rigid-Frame Steel Hangars

For turboprops and light jets, our rigid-frame hangars deliver the clear spans and load-bearing capacity required for aircraft such as the Pilatus PC-12, King Air 350, Phenom 100, or Citation CJ series. Rigid-frame construction allows for wide-bay doors, higher tail clearance, and custom design flexibility, including mezzanines, integrated workshops, or multi-aircraft storage layouts. Each structure is engineered to meet local codes, snow and wind loads, and aviation safety standards.

Why Choose Quicken Steel

Speed Meets Precision

Our prefabricated cold-formed steel systems are built for rapid assembly without sacrificing structural integrity. Faster erection times mean you’re housing aircraft sooner—and generating ROI faster.

Strength That Lasts

- Galvanized steel framing for superior corrosion resistance

- R-19 insulation options for thermal efficiency

- Architectural 24-gauge paneling for lasting aesthetic appeal

- Structural warranties backed by decades of performance

Flexible Configurations

Choose from multiple layout types to match your operational footprint:

- Nested T-Rows — maximum density for shared walls (6–10 bays per row)

- End Rows — enlarged corner bays for offices or larger aircraft

- Back-to-Back — dual-sided layouts for efficient land use

- Executive Singles — standalone hangars with integrated lounges or workshops

Built to Code, Built to Last

Every Quicken Steel hangar is designed and stamped to meet the latest national and regional standards:

- IBC 2024, ASCE 7-22, AISC 360, and AISI S100

- NFPA 409 Group III and UFC 4-211-01 compliance

- FAA site standards: AC 150/5300-13B and AC 150/5320-5D

- Regionally adjusted wind, snow, and seismic loads

- Integrated MEP chases, drainage, and fire suppression planning

Structural Framework Options

Functional Series (Municipal / Private Owner)

- PEMB rigid-frame structure

- 26-gauge Galvalume sheeting

- Optional vapor barrier or single insulation layer

- Sliding or bi-fold doors (manual or electric)

- Minimal interior finishes with LED options

- NFPA 409 Group III compliant

Quicken Premium Series

- Hybrid hot-rolled / cold-formed frame

- 24-gauge architectural panels

- R-19 roof and wall insulation, LED lighting, epoxy flooring

- Hydraulic one-piece doors with remote control

- Integrated drainage and conduit systems

- Optional mezzanine, office, or workshop bay

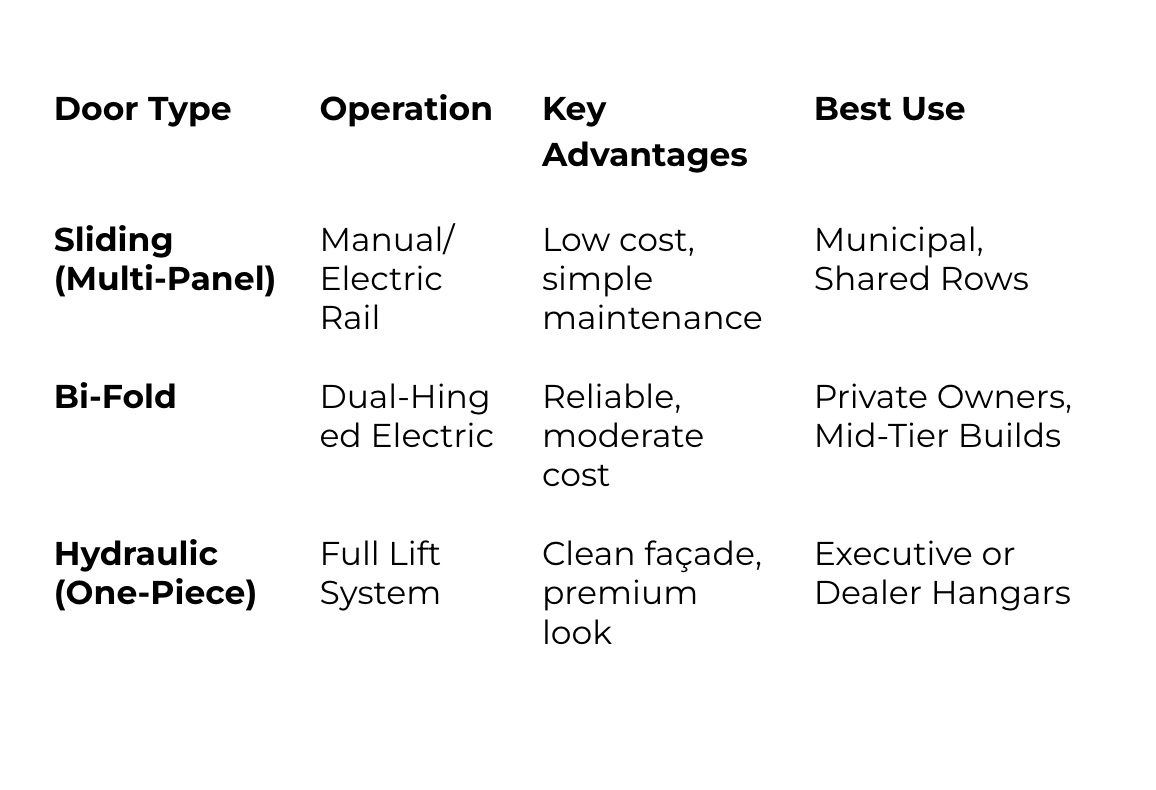

Door Systems for Every Application

Specifications at a Glance

Material & Finish Options

Wall Panel Color Options

Standing Seam Roof Panel Color Options

Quicken Steel — Built better to be your aviation hangar copilot

From design to delivery, every Quicken Steel hangar reflects precision engineering, American manufacturing, and aviation expertise.

We don’t just build hangars—we build complete aviation environments that scale with your operation.

Contact Us

Phone: 912-549-4050

Headquarters

188 Georgia Pacific Drive

Claxton, GA 30417

Texas Location

1325 114th St,

Grand Prairie, TX 75050